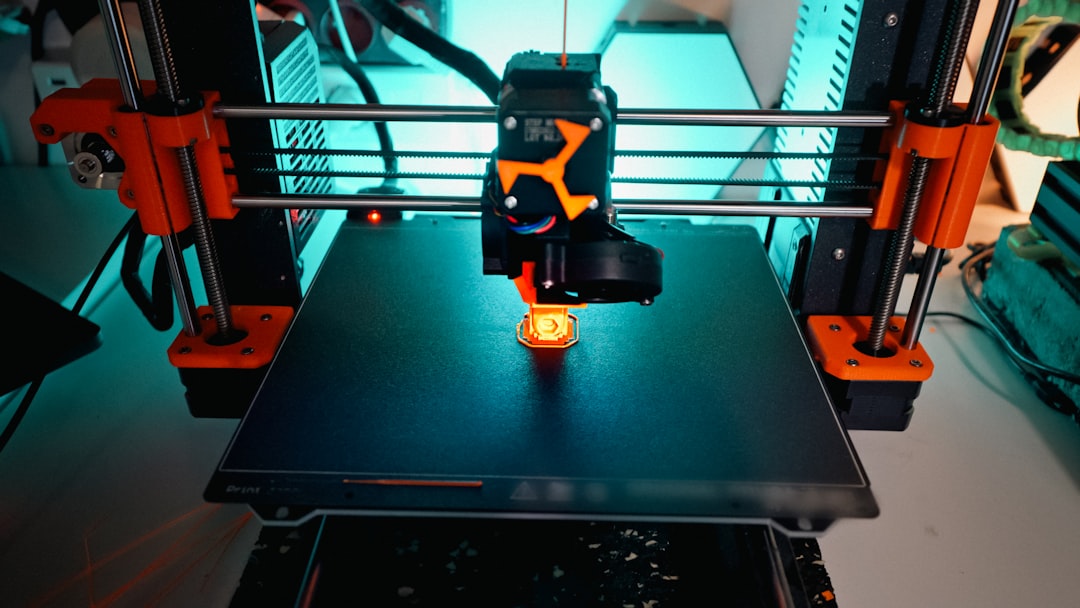

Dual extruder 3D printing is awesome. You can print two colors or use support materials. But sometimes, things go wrong. Don’t worry—we’re here to help! Let’s dive into some common issues and how to fix them.

1. Misaligned Nozzles

One nozzle prints perfectly, but the other is just… off. Sounds familiar?

Solution:

- Check nozzle heights. They should be level.

- Use your printer’s software to calibrate properly.

- Watch for wobbling beds or skewed axes.

If one nozzle scratches the surface, raise it slightly using Z-offset settings.

2. Stringing Between Nozzles

Spider webs on your print? That’s stringing.

What’s happening? The idle nozzle leaks a bit while the active one prints.

Fix it:

- Enable nozzle wiping or prime towers in your slicer settings.

- Turn on retraction for both nozzles, and fine-tune the values.

- Use materials with lower ooze potential, like PLA instead of TPU.

3. Heat Creep

You’re halfway through a job, and suddenly the print stops extruding. Ugh!

This could be heat creep. The heat travels up your hotend and softens the filament too early.

Try this:

- Clean your hotend. Gunk makes heat creep worse.

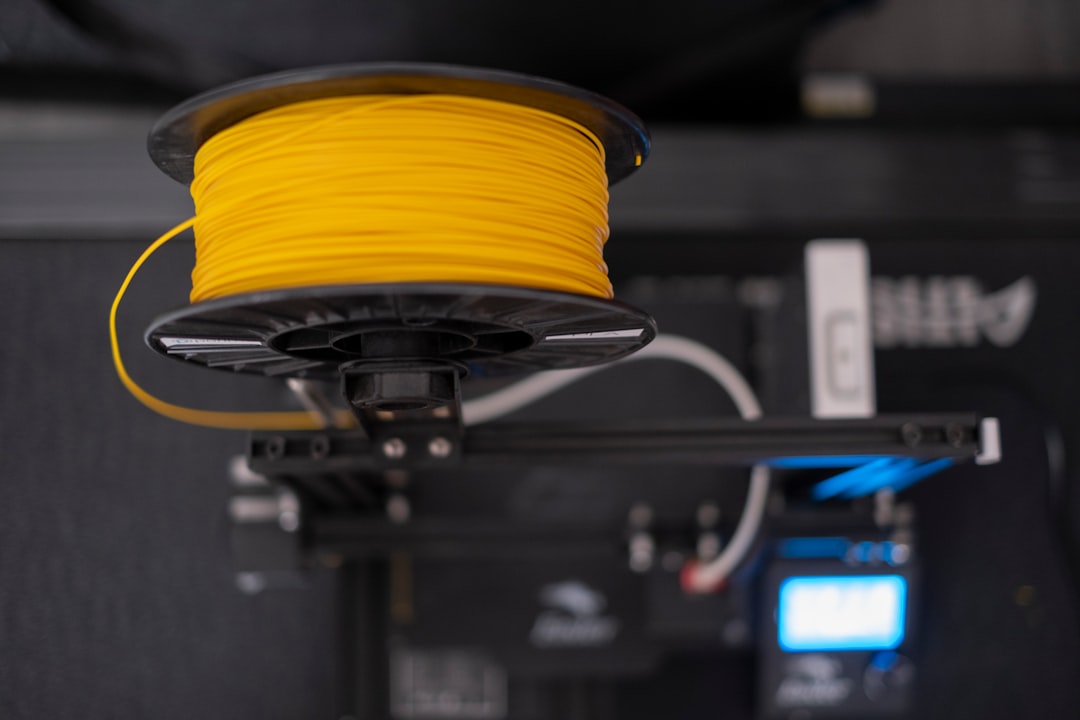

- Keep your filament cool and dry.

- Make sure the hotend fans run at full speed.

4. Inconsistent Colors or Support Material Trails

Your model looks like it has phantom color smears or support leftovers.

Why? Your nozzles might not be clean, or one is dragging extra filament.

How to fix it:

- Activate wipe towers or prime towers in your slicer.

- Pause between tool changes so the new nozzle can purge properly.

- Make sure each nozzle has enough “parking time” to avoid dripping.

5. Nozzle Crashes into the Print

Ouch. That scary thud sound mid-print? One nozzle just headbutted your print.

This happens when:

- One nozzle is lower than the other.

- Your slicer isn’t compensating for both nozzle offsets.

- The model has warped slightly, raising the surface.

Solution:

- Recalibrate both nozzles.

- Use a slicer with dual-extruder profiles, like PrusaSlicer or Cura.

- Enable dynamic nozzle lifting if your printer supports it.

6. Filament Jams

Click… click… oh no! Your printer sounds like it’s chewing gravel.

This jam could be due to:

- Incorrect temperature settings for one material.

- Too much pressure from the gear onto the filament.

- Dirty or worn-out hotend/nozzles.

What you can do:

- Heat up the nozzle and manually push filament through.

- Disassemble and clean the hotend if needed.

- Double-check your slicer settings for temperature and retraction.

7. Tool Change Takes Forever

Tick-tock… is your printer on a coffee break?

Long tool changes usually mean unnecessary movements or wait times.

Speed it up:

- Adjust wait times in your slicer’s tool change settings.

- Reduce purging time, but don’t eliminate it—that causes color bleed.

- Use only one extruder for big parts and bring in the second one for small details or supports.

Final Tips

Dual extruder printing can feel like juggling flaming swords at first. But once tamed, it’s magical!

- Keep nozzles clean—residue causes all kinds of chaos.

- Label your materials and assign matching profiles in your slicer.

- Start simple. Practice with dual-color name tags or keychains before jumping into intense models.

Now you’re ready to tackle those dual-extruder problems like a printing pro. Happy printing!